How do you Make a Supply Chain Sustainable? Key Strategies

“Every minute, the equivalent of one garbage truck of plastic is dumped into our oceans,” a startling statistic from the World Economic Forum that hits like a thunderbolt. This isn’t just an environmental crisis, it’s a wake-up call for businesses worldwide. In the heart of this storm is the supply chain – the backbone of global commerce, yet often a contributor to environmental degradation. As we step into 2023, the call for sustainable supply chains has shifted from a whisper to a roar.

Companies are facing a critical crossroad: continue with business as usual and risk irreversible damage to the planet and their reputation, or pivot towards sustainability and redefine their role in the global market.

From innovative sourcing methods to the magic of reverse logistics, we’ll explore how businesses can turn their supply chains into powerful tools for positive change.

Table of Contents

Understanding the Sustainable Supply Chain

A sustainable supply chain is all about creating a balance. This balance involves meeting current needs without compromising future generations’ ability to meet theirs. It’s a blend of environmental stewardship, social responsibility, and economic viability.

Why go sustainable? It’s simple. Sustainable supply chains reduce environmental impact, build social equity, and drive economic growth. They’re not just good for the planet, they’re good for business too.

Despite the clear benefits, the road to sustainability is paved with challenges. From adapting to green technologies to managing the costs of sustainability initiatives, businesses often struggle to find the right balance.

Innovative Strategies for Sustainability

The journey to sustainability starts with the materials you choose. Sourcing materials responsibly means considering the environmental and social impact of their extraction and processing.

It’s not just what you make, it’s how you make it. Implementing energy-efficient practices in manufacturing can significantly reduce a supply chain’s carbon footprint.

The way products are transported and distributed plays a huge role in sustainability. Opting for eco-friendly transportation methods can make a big difference.

The Role of Technology in Sustainable Supply Chain

Big data isn’t just a tech trend, it’s a sustainability enabler. By analyzing supply chain data, businesses can identify inefficiencies and areas for improvement.

Let’s delve into some of these technologies and how leading companies are utilizing them to revolutionize their supply chains.

Data Analytics and Sustainability

- Walmart’s Big Data Approach: Walmart, a retail giant, has been leveraging big data analytics to enhance its supply chain sustainability.

By analyzing vast amounts of data, Walmart optimizes its routes for transportation, reducing fuel consumption and greenhouse gas emissions.

This data-driven approach has enabled Walmart to improve its delivery times while minimizing its carbon footprint.

- IKEA’s Inventory Management: IKEA, known for its commitment to sustainability, uses advanced data analytics for efficient inventory management.

By accurately predicting demand, IKEA reduces overproduction, thereby minimizing waste and resource consumption.

This smart inventory management is a key component in IKEA’s journey towards a more sustainable supply chain.

Automation and AI

- Amazon’s Robotics: Amazon has been at the forefront of using automation in its supply chain. The company employs over 200,000 robots in its warehouses, significantly reducing the need for human labor and increasing efficiency.

These robots help in sorting, packing, and transporting goods, leading to faster delivery times and reduced energy usage.

- DHL’s AI-Powered Logistics: DHL, a global logistics leader, utilizes AI to optimize its delivery routes and manage its logistics network. AI algorithms analyze traffic patterns, weather conditions, and delivery schedules to find the most efficient routes.

This not only speeds up the delivery process but also reduces fuel consumption and emissions.

IoT and Sustainability

- Maersk’s IoT Integration: Maersk, one of the world’s largest shipping companies, has integrated IoT (Internet of Things) into its operations.

By using sensors on ships and containers, Maersk tracks the condition of goods in real-time, ensuring optimal temperature and humidity levels.

This technology reduces the risk of spoilage, especially for perishable goods, thereby decreasing waste and improving efficiency.

- Cisco’s Supply Chain Visibility: Cisco Systems uses IoT to gain visibility into its supply chain. Sensors and connected devices provide real-time data on the location and condition of goods.

This level of transparency allows Cisco to respond quickly to any disruptions, ensuring a more resilient and sustainable supply chain.

These examples illustrate how technology is not just a tool for efficiency but a catalyst for sustainability.

Reverse Logistics – A Key to Sustainable Supply Chain

It’s the process of moving goods from their final destination for the purpose of capturing value, or proper disposal. In the context of e-commerce and retail, it’s about managing returns and unsold inventory effectively.

Effective reverse logistics can turn a potential loss into a gain. It’s about finding new homes for unsold or returned items, rather than sending them to landfills.

Here, Happen Ventures shines. Their focus on managing unsold inventory and returns helps businesses reduce waste and improve sustainability.

Building a Sustainable Supply Chain Network

No business is an island, especially when it comes to sustainability. Forming partnerships along the supply chain can amplify sustainability efforts.

These are the cornerstones of a sustainable supply chain. Being open about practices and taking responsibility for impacts are crucial.

Staying ahead of regulations not only avoids penalties but also drives businesses towards more sustainable practices.

Measuring the Impact

What gets measured gets managed. Key performance indicators for sustainability can include carbon footprint, waste reduction, and energy efficiency.

Sustainability is a journey, not a destination. Regularly assessing and adapting strategies is essential for long-term success.

A Case Study from Unilever

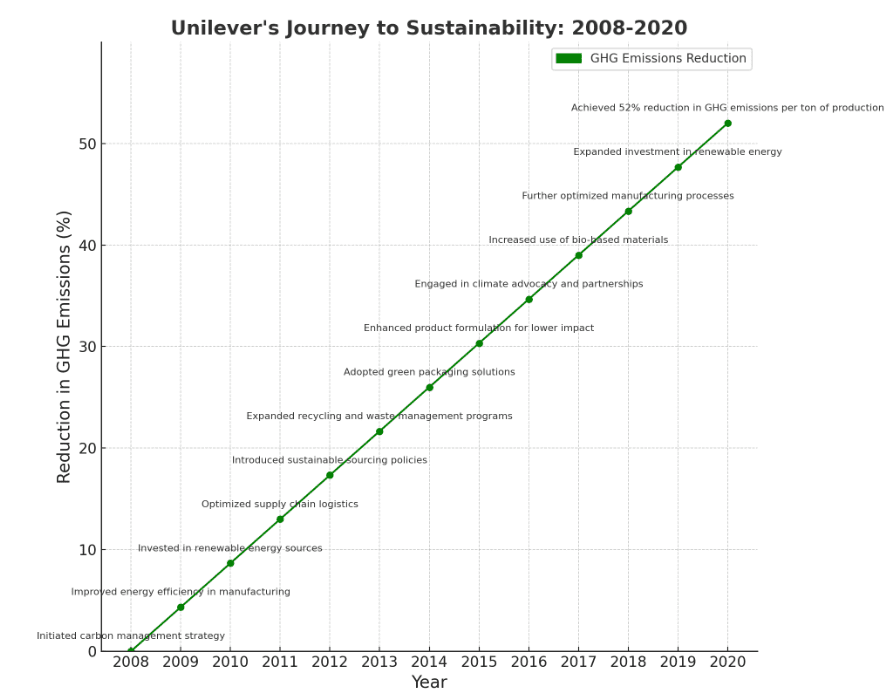

Unilever, a global leader in consumer goods, has been a pioneer in sustainability. According to their 2020 report, Unilever achieved a 52% reduction in greenhouse gas emissions per ton of production since 2008.

This significant decrease highlights the impact that a comprehensive sustainability strategy can have on a company’s carbon footprint.

Preparing for the Future

From circular economies to blockchain technology, the future of sustainable supply chains is exciting and full of potential.

Staying agile and open to new ideas is key for businesses to remain sustainable in the ever-evolving global market.

As we wrap up, remember that building a sustainable supply chain is not just a good business practice, it’s a necessity for a better world.

Conclusion

In conclusion, creating a sustainable supply chain is a complex but rewarding journey. It’s about making thoughtful choices at every step, from sourcing to logistics. By embracing innovation, collaboration, and continuous improvement, businesses can not only reduce their environmental impact but also build a stronger, more resilient operation. Let’s take these insights and turn them into action for a greener, more sustainable future.